Japanese wind bells are well- known for the sound that they produce. Unlike machine made copper bells, these bells are hand made and can be customized as desired.

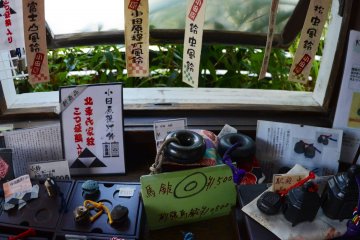

Odawara is known for producing wind bells, and there is one family that has been making them for 7 generations. Their company, known as Kashiwagi, was established in 1686 when the Edo period (1600-1868) was blooming. Kashiwagi is located 10-15 minutes by walk from the station. It isn't advertised as much as other attractions in Odawara.

I had the opportunity to peek into the workshop of this factory come shop. The bell makers prefer to keep the manufacturing process a secret, as there are a lot of new competitors that are trying to reproduce these authentic bells using modern techniques. I learned that a strict tradition is followed in the process of bell making. The metal used is an alloy of copper, tin and zinc; but it isn't brass, as the proportions are different. The main purpose of such an alloy is to produce the best sound. And after centuries of experimentation, they came up with the alloy that they use today.

Kashiwagi bell makers use ready made moulds to cast these bells. A mould of sand can also be used to cast these bells with custom designs. Recently they have been allowing people to get involved in this as a recreational activity. For approximately 3000 yen, you could make 2 wind bells and customize them with any writing or design. I didn't wait around, and got right away to bell making. The instructor doesn't know very good English, but his actions are self explanatory.

First you are given a piece of paper and asked to draw your designs on the back and front. If your design is in writing, you have to copy it in sketch paper and re-write it as a mirror image. Then you are given 2 sets of different moulds. These moulds are made of sand. You have to copy your design on to the moulds using crayon, and this can be a little difficult as the mould is curved. After the moulds are ready with the design, the instructor will give you an engraving tool. Using the sharp tip, you have to make a deep impression on the mould. This process was time consuming for me, and took me an hour or so.

The design stage is complete. The next step involves getting the mould ready for casting. Using a special glue, you have to stick the two sides of the mould together, and caution must be taken that the glue doesn't enter inside the mould curvature. Then you have to seal it for a while using clips and wait for the glue to dry. Lastly, you have to stick the inner mould block that makes the bell hollow instead of a solid structure.

Unfortunately, they don't let you be involved in the metal casting process, but in two weeks the bell is ready to pick up, and you could have the bell shipped to you internationally for 1500 yen. I was told that after casting they paint it, polish it, and attach the other parts that create the sweet sounds in the bell.

This 2-3 hour activity will make you feel like a Japanese bell maker from ancient times. The workstation and factory enhances that antique atmosphere too. This experience is definitely one of a kind, and is a must do in Odawara.